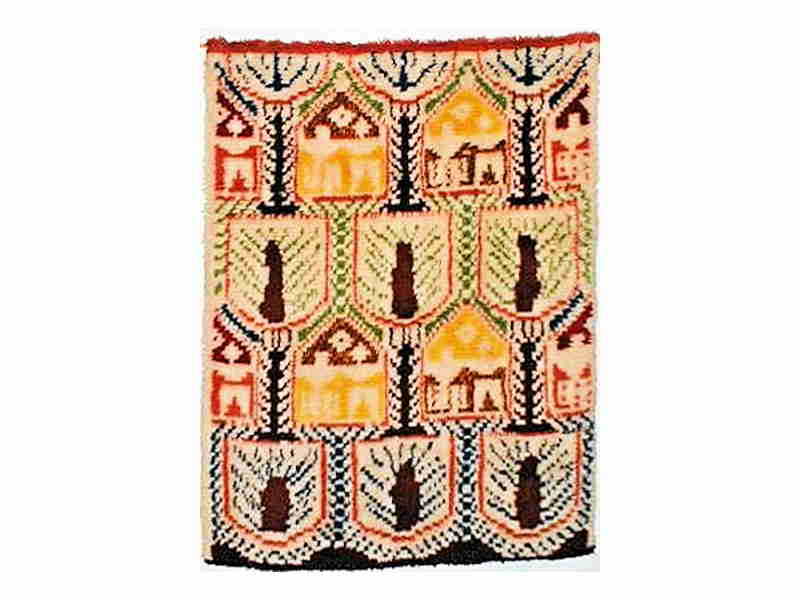

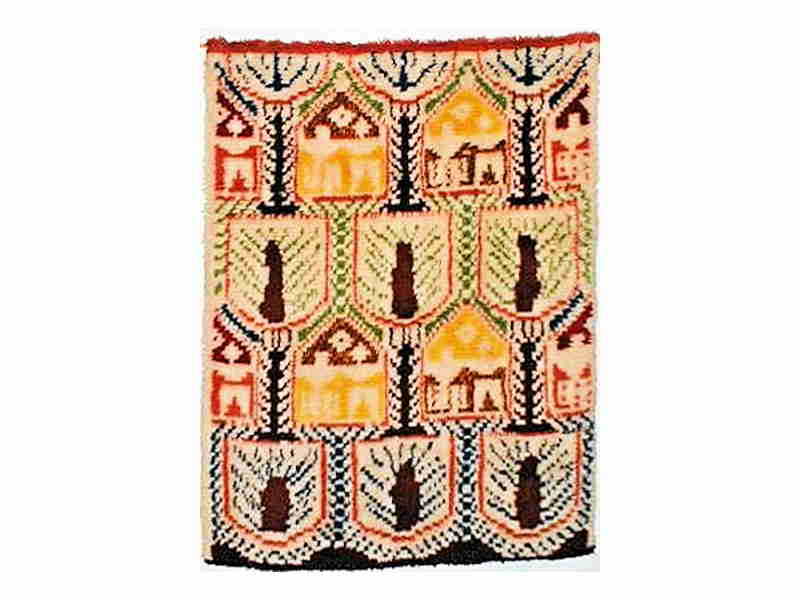

Finnish Rya Rugs

Finnish Textiles – Rya Rugs

Here are a few examples of vintage Finnish rya rugs. The pile for a rya rug or tapestry is woven or sewn onto a wool backing.… Read more...

Information,tips and techniques about weaving, warps, looms and textiles.

Finnish Textiles – Rya Rugs

Here are a few examples of vintage Finnish rya rugs. The pile for a rya rug or tapestry is woven or sewn onto a wool backing.… Read more...

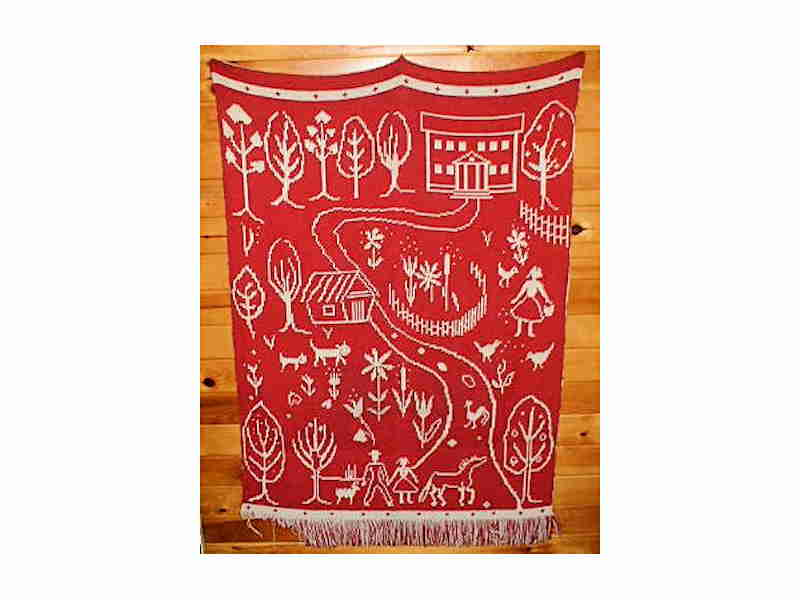

Raanu weavings use a cotton warp and a wool weft. The wool weft yarns are generally quite fine and many colours are used to create the complex designs of this weft-faced rep weave.… Read more...

FI – Täkänä

Here are some examples of Finnish weaving techniques of Double weave Pickup and Täkänä.

During a trip to Ontario, I had the opportunity to view some wonderful examples of Finnish textiles. Here are some photos of them.… Read more...

From rope to fine tablecloths, hemp has been used by industry and for textiles for many centuries.… Read more...

I had the pleasure of meeting Kat Walton, an accomplished drop spindler and weaver. Here are some samples she wove using a rigid heddle loom.… Read more...