How to Warp a Loom – and the Great Moth Invasion

You can save a considerable amount of time when warping a loom if you have an old warp on the loom with a similar threading pattern.… Read more...

You can save a considerable amount of time when warping a loom if you have an old warp on the loom with a similar threading pattern.… Read more...

10 Steps to Warping – Step 10 – Tying the Warp

When the warp has been evenly wound on to the back beam, you are almost ready to weave.… Read more...

10 Steps to Warping – Step 9 – Beaming the Warp

Once the warp threads have been securely tied to the back apron rod, you are ready to begin to wind the remaining warp on to the back beam.… Read more...

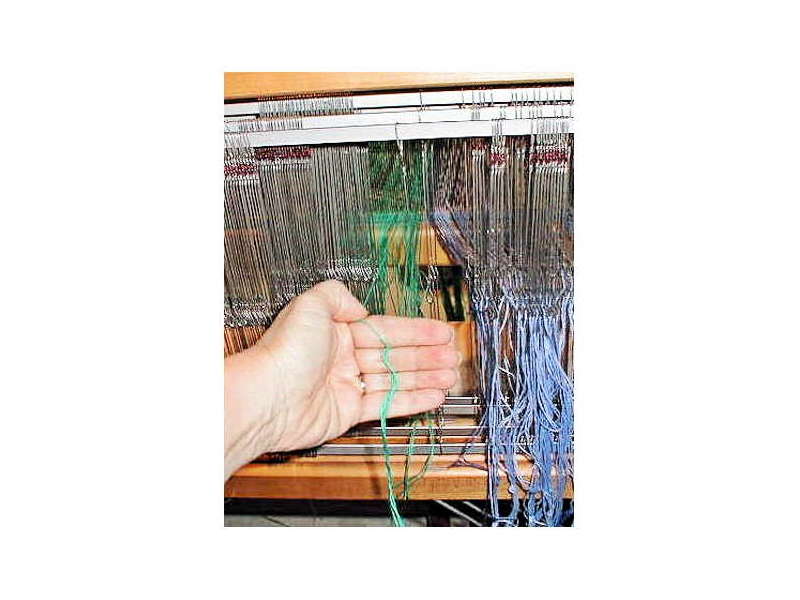

10 Steps to Warping – Step 8 Thread the Heddles

When all of the warp ends have been sleyed through the reed, I move to the back of the loom.… Read more...

10 Steps to Warping – Step 7 – Sley the Reed

Once you have removed the warp chain from the warping board it is ready to be transferred onto the lease sticks on your loom.… Read more...

10 Steps to Warping – Step 6 – Wind a Warp Chain

How to remove the warp from the warping board – safely.… Read more...