10 Steps to Warping – Step 6 – Warp Chains

This post has been updated and moved to:

10 Steps to Warp: Warp Chain… Read more...

10 Steps to Warping – Step 6 – Warp Chains

This post has been updated and moved to:

10 Steps to Warp: Warp Chain… Read more...

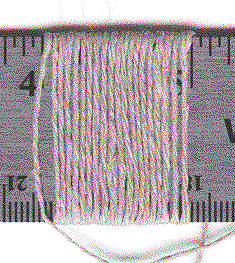

Wind Warp

This post has been updated and moved to:… Read more...

10 Steps to Warping – Step

This post has been updated and moved to:… Read more...

10 Steps to Warping – Step 3

This post has been updated and moved to:

10 Steps to Warp: Reed Size… Read more...

10 Steps to Warping – Step 2 – The Sett

This post has been updated and moved to:… Read more...

10 Steps to Warping – Step 1

There are lots of different ways to warp a loom. If you use another method, that’s great!… Read more...