Synthetic Dyes and Colour

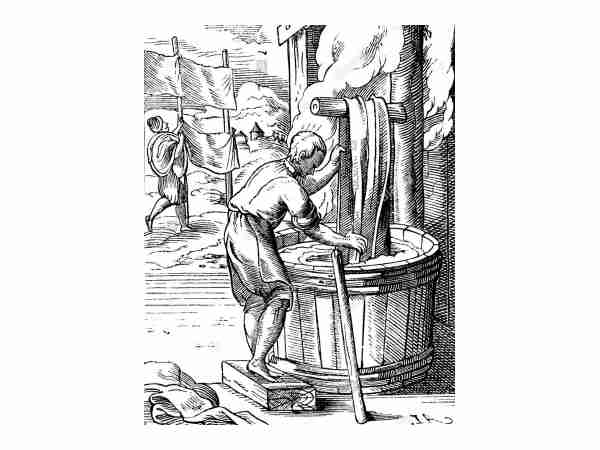

Information about how to dye yarn using synthetic dyes.

How-to information and supplies for the home dyer.

Synthetic Dyes and Colour

Information about how to dye yarn using synthetic dyes.

Kool-Aid Mittens

Kool-Aid Mittens

I finished my mittens last week. The fiber was Kool-aid dyed. The six colours are from three packets.

Since I am now living in a small flat in London, I have had to change my dye methods to working in a small space.… Read more...

This is a dye exercise that allows you to create over 120 dyes using just 3 colours.… Read more...

Dyes and color in the classroom.

Easter Egg Dye Project

How to dye some eggs and wool this Easter with natural dyes you can find in your kitchen.… Read more...

Rainbow Dyed Silk